GHSP. DFMA transformation across the enterprise

Enterprise journey to embed DFMA, governance, rollout tactics, and the impact on innovation, lead time, and quality.

Enterprise journey to embed DFMA, governance, rollout tactics, and the impact on innovation, lead time, and quality.

A large multinational manufacturer used DFMA on a flagship business/financial systems product to cut parts, cycle time, and WIP—projecting more than $3M in annual savings from a single machine.

How a center-led model matures DFMA practice after initial wins. Embedding methods across functions and products.

Five cross-functional teams used DFMA to accelerate decisions and simplify designs. Showing how concurrent engineering pairs with DFMA practice.

How a global tech organization scaled DFMA across teams. With measurable effects on time and cost.

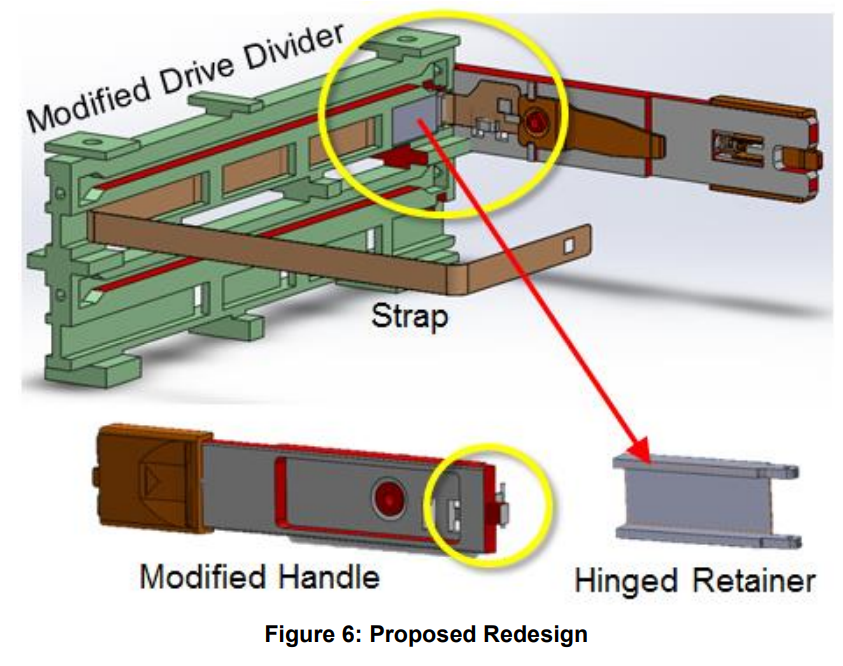

DFMA should-cost analysis guided a full redesign of NCR Voyix’s 2760 POS terminal, slashing part count, assembly time, suppliers, and manufacturing labor cost.

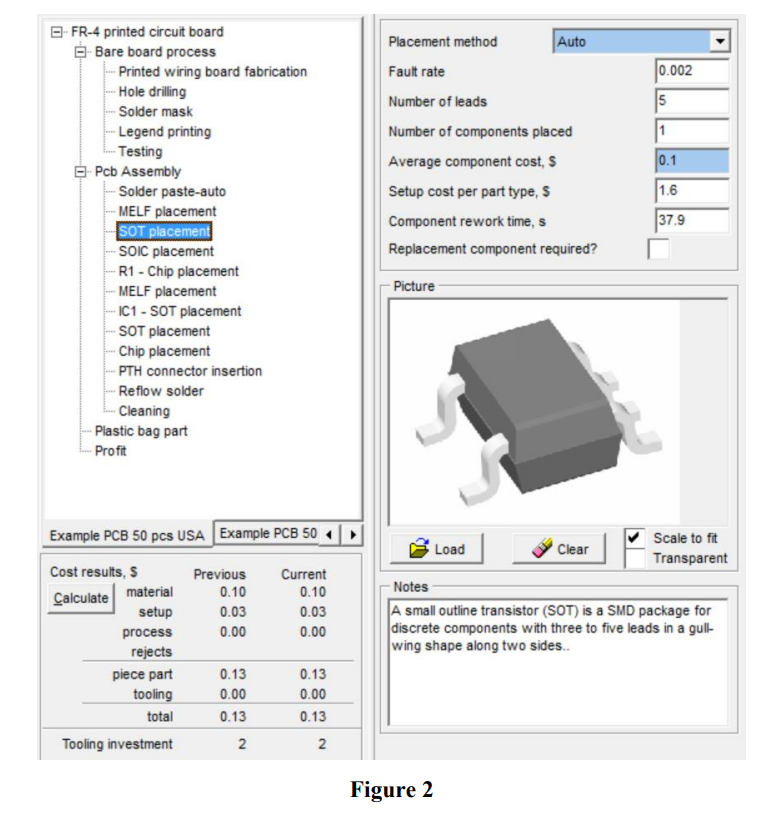

International Game Technology used DFMA to redesign a critical electronic box in its gaming machines, cutting part costs and assembly time for a 40% total cost reduction.

Breaking down PCB assembly cost drivers to improve supplier negotiations and design choices.

Real-world ROI patterns for DFMA in LV/HV environments and supplier negotiations. What to track and how to act.

Practical approaches to supplier costing when volumes are low and mix is high. Tying DFMA to sourcing and negotiations.

Systematic DFMA analysis cut material and assembly costs while improving throughput and DFA Index.

DFMA enabled custom. High-mix product teams to cut parts and assembly effort while meeting cost targets.

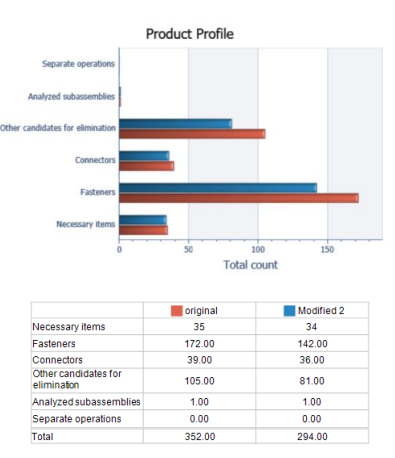

Concept-phase DFMA reduced parts from 352 to 294 and improved DFA Index. Delivering assembly-time and cost benefits early in design.

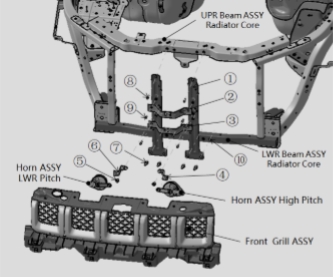

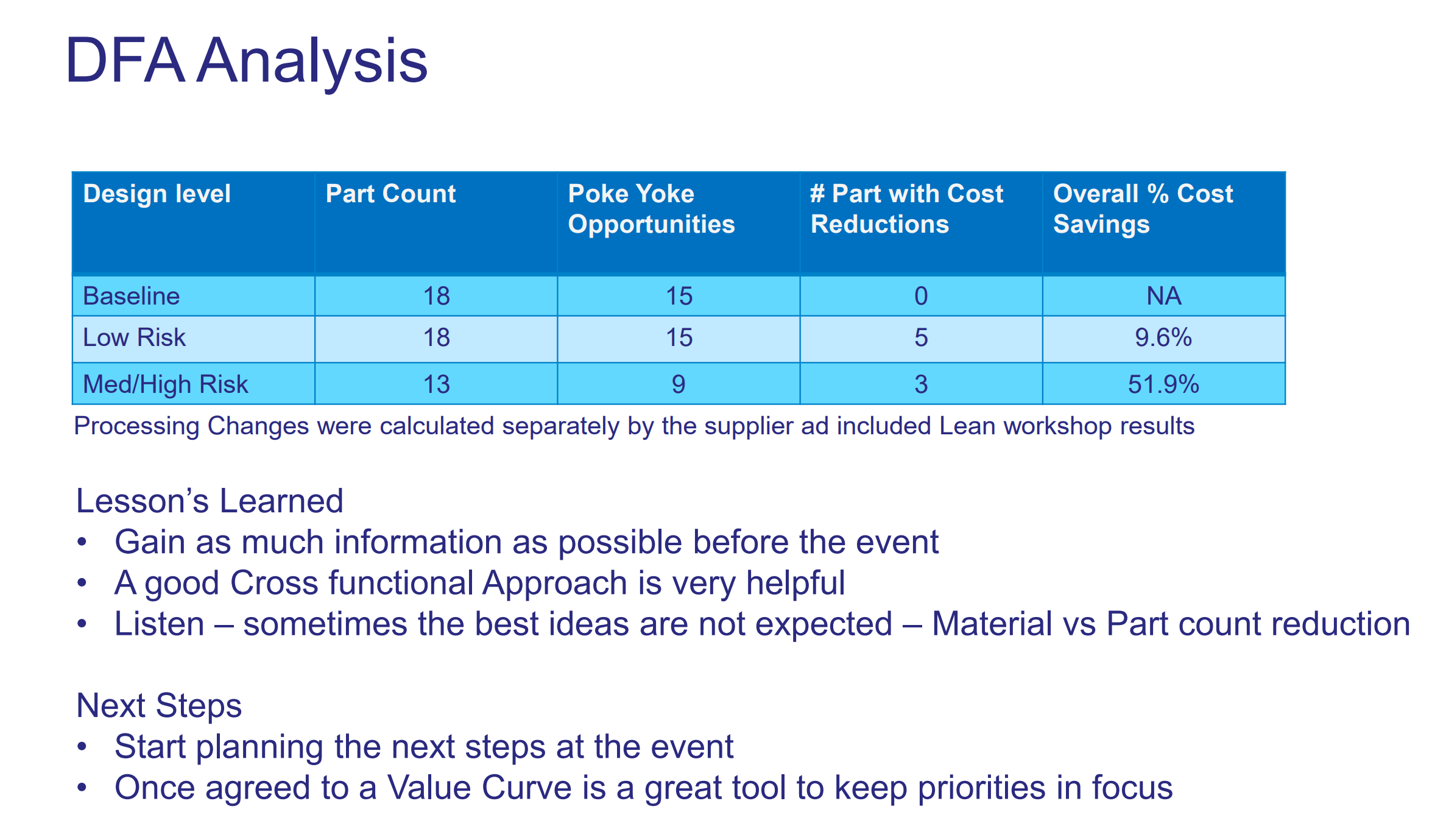

At BAIC, a cost and quality risk bumper assembly was re-engineered with DFMA ahead of a model refresh. Addressing fasteners, interfaces, and manufacturability.

A new Tier 3 engine prompted cost-effective redesign choices guided by DFMA.

Baseline DFA analyses and on-site workshops helped a seating group iteratively remove assembly inefficiencies under tight timelines.

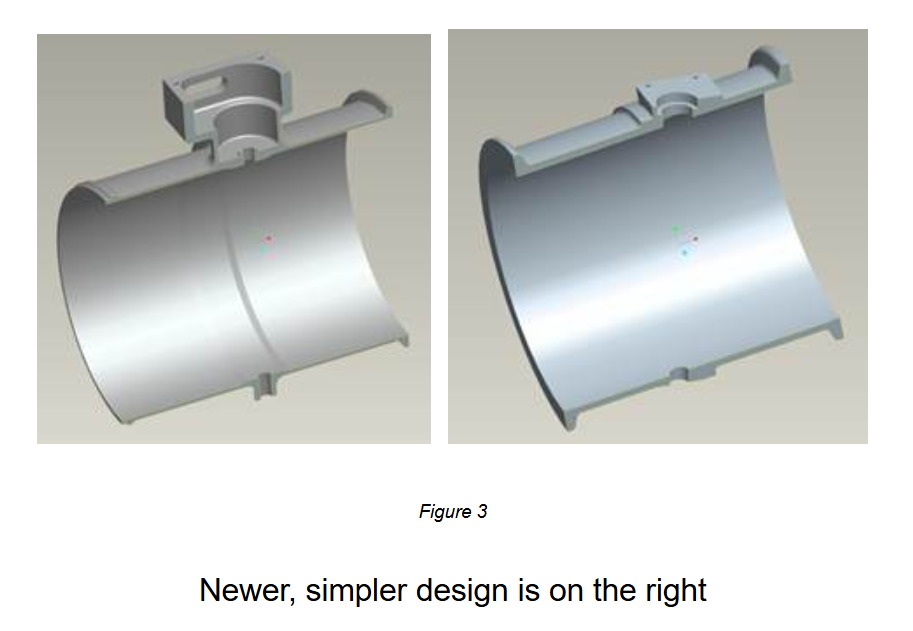

Replacing a complex steel assembly with two structural moldings cut assembly operations and part count. Simplifying end-of-life recycling.

Significant part-count reductions while maintaining quality and reliability across the 7400 Reach-Fork family.

Lessons from a major medical OEM on structuring DFMA for cost reduction. Cross-functional execution, change management, and measurable design simplification.

Self-aligning features, material reviews, and fewer components. Kicked off by a benchmark DFA. Drove cost and quality improvements.

With early cost and assembly data, engineers avoided BOM reuse by default and made profit-driven decisions earlier.

DFMA enabled a hybrid mass spectrometer to hit a narrow market window with simpler assemblies and faster builds.

A multinational manufacturer applied DFMA to a complex business and financial systems machine, cutting parts, cycle time, and WIP, with projected annual savings of more than $3M from a single product.

A concurrent engineering team used DFMA to redesign a modular laptop platform, dramatically cutting assembly, test, and PWB times while improving serviceability and flexibility.

DFMA simplified a commodity computer mouse into a screwless, stackable assembly, cutting parts, assembly operations, and material cost while making repair and automation easier.

A major manufacturer used DFMA to redesign a rugged firefighter flashlight, reducing parts, processes, and assembly time while improving consistency and serviceability.

DFMA guided a full firehose reel redesign to meet updated standards, halving parts, assembly time, and total costs while simplifying mounting and assembly.

Applying DFMA at concept helped the team meet cost targets and deliver on time and on budget.

Handheld readers, mobile radios, and kiosks benchmarked with DFA to cut parts and assembly time in redesign cycles.

DFMA-led redesigns delivered about $700,800 annual savings on an OC-3 shelf and about $3.45M on a redesigned filler pack.

Cross-functional teams trained in DFA delivered immediate returns via hands-on analyses.

Using DFE with Boothroyd Dewhurst to simulate end-of-life disassembly and environmental impact informed a better display design.

DFMA improved designs for water filtration and a coffee maker. Cutting parts and assembly time.

Tying DFMA into lean, TCO, VAVE, and supply chain to meet affordability goals on major programs.

Integrated product development teams used DFMA and Six Sigma to re-engineer key fighter aircraft structures, dramatically cutting parts, weight, and total cost.

A defense OEM applied concurrent engineering and DFMA to an electronic box in a tank program, simplifying the design and cutting steps, part count, and total cost in half.

DFA analysis across several areas yielded large reductions in part count, install time, weight, and overall cost.

Hard-won insights on moving work to China and back. Cost, risk, and capability lessons that inform DFMA trade-offs.

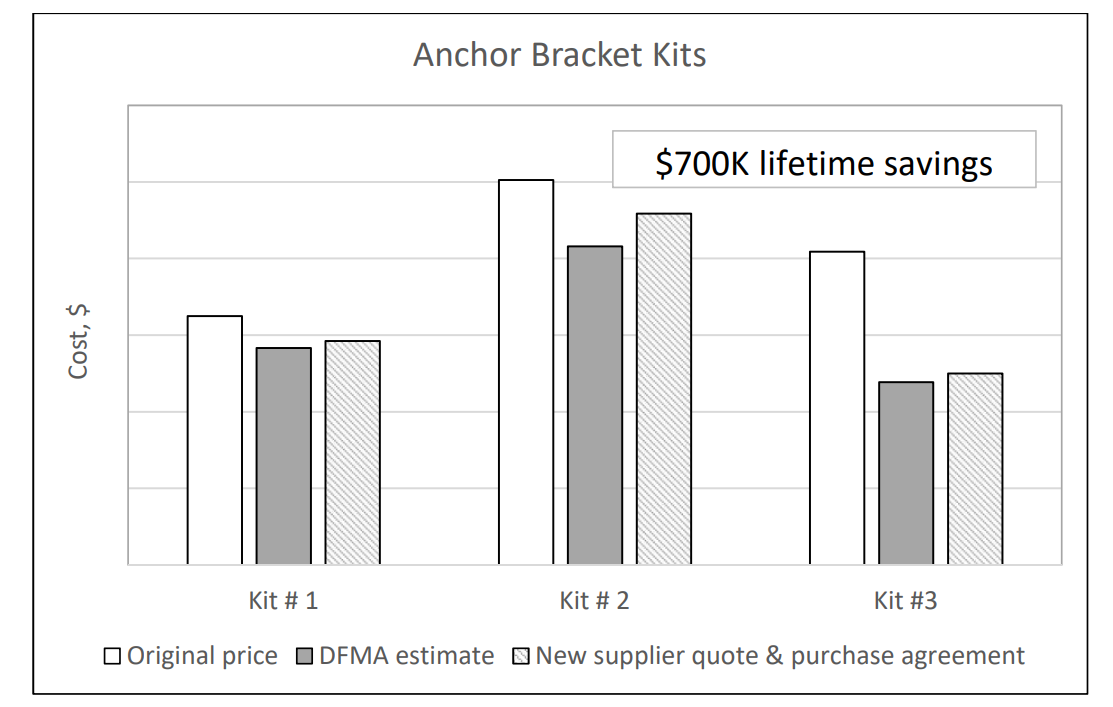

Nick Dewhurst’s executive presentation covers DFMA history, the three main uses of DFMA, and a plastic clip case where DFMA drove $361k annual cost avoidance in supplier negotiations.