What is DFMA?

DFMA (Design for Manufacturing and Assembly) is a systematic engineering methodology that evaluates product designs for both ease of manufacturing and ease of assembly. The goal is to simplify the product—fewer parts, simpler processes, lower total cost—without sacrificing function.

DFMA combines two complementary disciplines: DFA (Design for Assembly) asks whether each part is necessary and how easily the remaining parts go together. DFM (Design for Manufacturing) asks whether each part can be produced efficiently and cost-effectively given the chosen process and production volume. Together, they ensure that improvements in one area don't create problems in the other.

On this page

Who should care about DFMA?

DFMA touches every function in the product-development lifecycle. The specific value depends on the role:

- Quantify assembly complexity and part-count targets

- Get should-cost estimates before requesting supplier quotes

- Iterate on geometry with immediate cost feedback

- Make process-selection trade-offs with real data

- Reduce production complexity and floor-level issues

- Shorten ramp-to-volume with simpler assemblies

- Fewer fixtures, setups, and secondary operations

- Higher first-pass yield and lower rework

- More predictable schedules and budgets

- Should-cost data for supplier negotiations

- Sourcing-scenario analysis across regions

- Reduced BOM complexity and supply-chain risk

- Drive cost-out and margin improvement

- Accelerate time-to-market on new programs

- Improve product reliability and warranty performance

- Align engineering decisions with financial targets

How DFMA works: DFA + DFM

DFMA is applied in a specific sequence. DFA comes first—simplify the product by eliminating unnecessary parts and reducing assembly complexity. Then DFM optimizes each remaining part for cost-effective manufacturing. This order matters: there's no point optimizing a part for manufacturing if that part can be eliminated entirely.

| Discipline | Focus | Key questions | Typical output |

|---|---|---|---|

| DFA | The whole assembly | Is this part necessary? Can it be combined with another? How hard is it to handle and insert? | Reduced part count, lower assembly time, design-efficiency index |

| DFM | Each individual part | What's the best process? What drives cycle time? Where's the cost coming from? | Should-cost per part, process selection, cost-driver breakdown |

| DFMA | Product-level optimization | What's the total cost? Where does the biggest opportunity sit? Which trade-offs matter? | Total product cost, part-count target, design-to-cost roadmap |

Design for Assembly (DFA)

Design for Assembly (DFA) focuses on reducing the number of parts in a product and making the remaining parts easier to assemble. It is the starting point of DFMA because eliminating a part saves not just the part cost, but also its assembly cost, inventory cost, and potential failure mode.

Core DFA strategies

Apply the minimum-part-count criteria: does the part move relative to its neighbor? Must it be a different material? Must it be separate for assembly or service? If none apply, the part is a candidate for elimination or consolidation.

Design parts that self-locate, self-align, and don't tangle. Symmetry, chamfers, and generous clearances reduce operator effort and enable automation.

Replace screws and bolts with snap-fits, adhesives, or welding where appropriate. Each eliminated fastener removes a handling step, a tool, and a potential quality escape.

Parts that can be assembled from a single direction (top-down Z-axis), with no re-orientation, are compatible with automated assembly and faster manual assembly alike.

For a complete overview of DFA principles and methodology, see Design for Assembly (DFA).

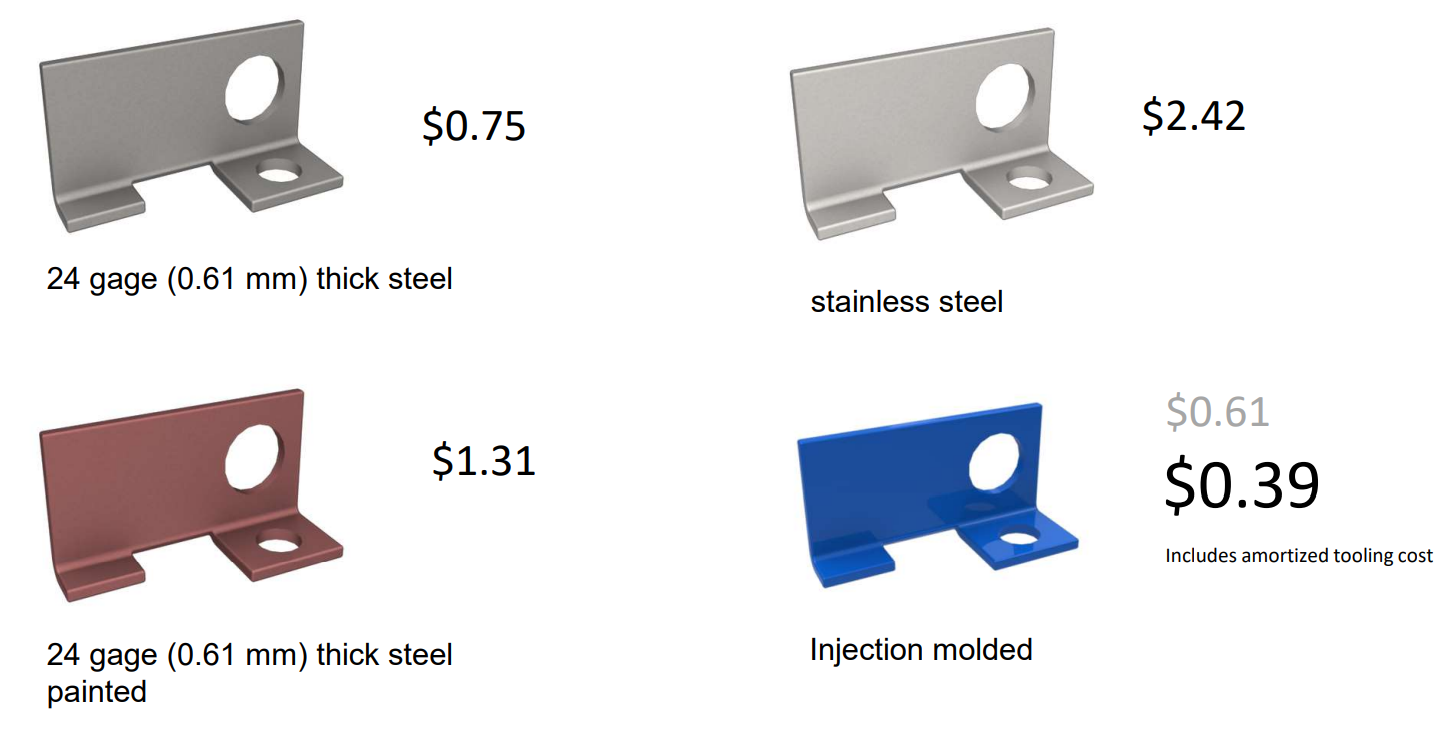

Design for Manufacturing (DFM)

Design for Manufacturing (DFM) optimizes each part for cost-effective production by modeling the manufacturing process—material, cycle time, setup, tooling, and secondary operations—and showing designers exactly where the cost comes from. With this visibility, engineers can iterate on geometry, tolerances, and process choice to hit cost targets.

Key DFM principles

- Design to the strengths and constraints of the target process

- Injection molding: uniform walls, draft angles, minimized undercuts

- Machining: simplify geometry, reduce setups, choose machinable materials

- Sheet metal: design for efficient cutting, bending, and nesting

- Know which features drive cycle time, tooling, and secondary ops

- Relax non-functional tolerances to enable faster feeds and fewer rejects

- Optimize buy-to-fly ratio through geometry and stock-form selection

- Right-size surface finish to functional requirements

Manufacturing processes modeled in DFMA

For the full DFM methodology and how it connects to should-cost analysis, see Design for Manufacturing (DFM).

Global manufacturing cost data

DFM cost analysis is only as good as the cost inputs behind it. DFMA Global Manufacturing Profiles provide region-specific data—wages, overhead structures, energy costs, and related factors—for 22+ countries, so teams can model the real economics of production in each region rather than relying on generic averages.

- Country-level labor rates by manufacturing sector

- Overhead structures and burden rates

- Energy costs by region

- Material pricing by local availability

- Logistics and landed-cost factors

- Compare should-costs across sourcing regions

- Run tariff and logistics scenarios before committing

- Guide process selection where labor vs. automation trade-offs differ

- Right-size tolerances and secondary ops to regional capability

- Support supplier negotiations with region-aware benchmarks

Typical DFMA outcomes

DFMA results vary by product complexity, production volume, and how early the methodology is applied. These ranges represent what teams typically achieve:

Part-count reduction

Assembly-time reduction

Lower tooling, supply chain & total cost

Beyond direct cost savings

Fewer parts mean fewer interfaces, fewer tolerance stackups, fewer potential failure modes, and fewer opportunities for assembly error.

Simpler assemblies require fewer drawings, fewer tools, fewer qualifications, and shorter production ramps. Teams reach volume faster.

Consolidated parts reduce the number of suppliers, purchase orders, inspection points, and inventory SKUs.

Fewer parts, less material waste, shorter cycle times, and reduced energy consumption contribute to lower environmental impact.

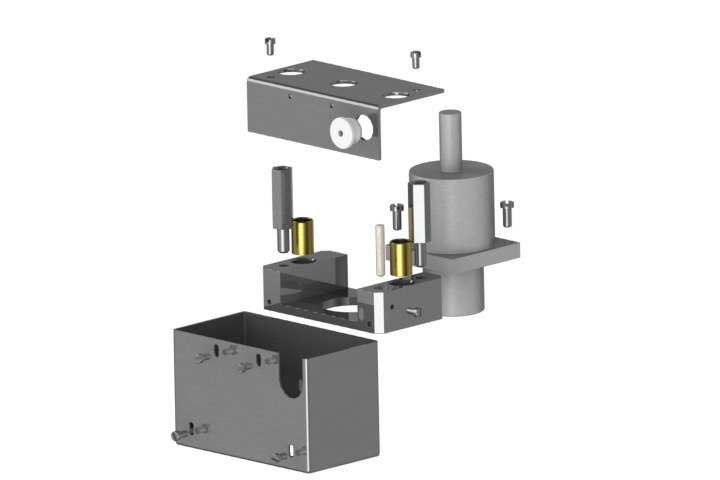

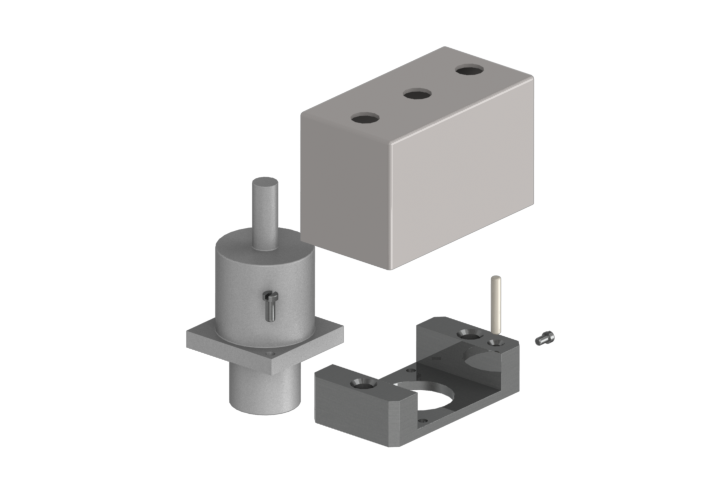

Worked example: motor-drive assembly

Here's an illustrative before-and-after comparison showing how DFA analysis simplifies a motor-drive assembly—then DFM optimizes the remaining parts:

| Metric | Before DFMA | After DFMA | Improvement |

|---|---|---|---|

| Total parts | 29 | 8 | 72% reduction |

| Separate fasteners | 12 | 2 | 83% reduction |

| Assembly time (est.) | 210 sec | 72 sec | 66% reduction |

| Assembly operations | 22 | 8 | 64% reduction |

| DFA index | 7% | 62% | Near theoretical minimum |

Key takeaway: 21 parts were eliminated or consolidated by applying the minimum-part-count criteria. The remaining 8 parts were then optimized with DFM—selecting the right process, simplifying geometry, and relaxing non-functional tolerances—to minimize per-part manufacturing cost.

Values are illustrative and based on a representative motor-drive assembly. Actual results depend on product complexity, production volume, and design maturity. See DFMA case studies for published results across industries.

When to apply DFMA

DFMA delivers the most value early in the design process—during concept selection and detail design—before tooling commitments lock in cost. But it's also effective as a benchmarking and cost-reduction tool on existing products.

| Stage | DFMA application | Value |

|---|---|---|

| Concept design | Compare architectures using DFA part-count analysis | Select the simplest concept before investing in detail design |

| Detail design | Full DFA + DFM on each subassembly and part | Converge to target cost with specific geometry and process decisions |

| Pre-production | Should-cost analysis for supplier negotiation | Negotiate from detailed cost breakdowns, not guesswork |

| Existing products | Benchmark current design and identify cost-out opportunities | Find 15–40% cost reduction in mature products with no functional change |

| Competitive teardown | Analyze competitor products for cost and design efficiency | Quantify competitor cost structure and identify design advantages |

Frequently asked questions

What does DFMA stand for?

DFMA stands for Design for Manufacturing and Assembly. It is a systematic approach that simplifies product designs—reducing part count, assembly steps, and process complexity—to cut cost, shorten time-to-market, and improve quality.

How is DFMA different from DFM or DFA alone?

DFA (Design for Assembly) optimizes how parts go together—minimizing part count, handling difficulty, and insertion complexity. DFM (Design for Manufacturing) optimizes how individual parts are made—selecting processes, simplifying geometry, and reducing cost drivers. DFMA combines both so that improvements in one area don't create problems in the other. DFA is applied first (simplify the product), then DFM optimizes each remaining part.

What results can DFMA deliver?

Typical outcomes include 20–50% part-count reduction, 10–30% assembly-time reduction, and significant savings in tooling, supply chain complexity, and total product cost. Results vary by product complexity and production volume.

Who benefits from DFMA?

Design engineers, manufacturing and operations teams, program managers, procurement, and executives seeking cost-out, faster production ramps, and higher product reliability all benefit from DFMA.

Does DFMA include global manufacturing cost data?

Yes. DFMA Global Manufacturing Profiles provide country-level cost inputs—wages, overheads, energy, and related factors—across 22+ countries. Teams use these data to compare should-costs by region, evaluate sourcing alternatives, and run tariff or logistics scenarios.

When should DFMA be applied in the design process?

DFMA delivers the most value when applied early in concept and detail design—before tooling is committed and manufacturing processes are locked. Changes at this stage are inexpensive. The same changes after production launch can cost 10–100× more. DFMA is also effective as a benchmarking tool on existing products to find cost-reduction opportunities.

See DFMA applied to your product

Bring a cost-critical assembly. We'll walk through a DFA part-count analysis and DFM should-cost breakdown—so you see exactly where cost lives and which design changes move the needle most.