DFMA: Product Simplification (Design for Assembly)

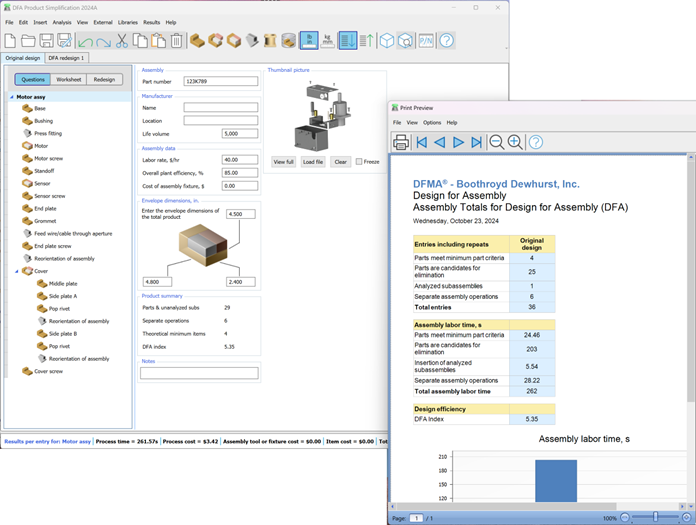

Simplify products, cut assembly time, and improve reliability. DFMA: Product Simplification uses an intuitive question-and-answer workflow to identify parts that can be consolidated or eliminated while maintaining 100% functionality. Applying industry-tested minimum-part criteria, the software highlights opportunities to reduce fasteners, simplify handling/orientation, and streamline fastening—resulting in a more elegant product that is easier and less costly to assemble.

Rate each part by how it’s grasped, oriented, moved, inserted, and fastened. Designs that assemble easily tend to cost less; DFMA quantifies those penalties so you can remove them by design.

Bring design, manufacturing, service, and sourcing into a single, objective discussion. DFMA provides a shared scorecard and concrete suggestions that move reviews from debate to decision.

Use the DFA Index to compare design alternatives internally—or against competing products—independent of product size or complexity. Track improvements as the design evolves.

Fewer parts and simpler interfaces mean fewer failure modes. Teams sharpen skills around theoretical minimum part count and eliminate unnecessary complexity early.

Pair Product Simplification with DFMA: Should Costing to evaluate process alternatives and piece-part costs. Together, they provide an early, defensible cost profile for planning and supplier collaboration.