DFMA® Services

The primary goal at Boothroyd Dewhurst is helping our customers achieve immediate results from DFMA® while establishing an internal DFMA® capability for the long term.

The objectives of our services are:

- Train teams in the principles and benefits of DFMA® concurrent engineering strategies.

- Help users realize immediate design improvements on their own company products.

- Encourage design creativity, teamwork and innovation.

- Establish a long term capability to develop profitable products that get to market quickly.

- Integrate DFMA® into the overall product development process.

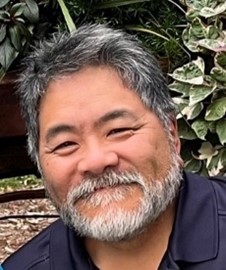

Chris Tsai, Director of Implementation Services

Chris has over 35 years of engineering, change management, and leadership experience. Most of that time was spent in the digital product design and manufacturing operations of Eastman Kodak Company spanning nearly all of their lines of business (i.e. copiers, scanners, consumer digital, professional imaging, and health imaging). He has held positions in product & tooling design engineering, manufacturing engineering, project management, quality management, and globalization. Early in his career, as part of a new product development (NPD) process reengineering effort, he established himself as a corporate subject matter expert in Value Analysis/Value Engineering (VA/VE) and Design for Manufacture & Assembly (DFMA®) and later expanded that expertise to Lean Six Sigma being certified as a Black Belt and becoming a corporate Lean Six Sigma instructor and mentor. He has developed and delivered corporate training and certification programs around the world.

Chris has over 35 years of engineering, change management, and leadership experience. Most of that time was spent in the digital product design and manufacturing operations of Eastman Kodak Company spanning nearly all of their lines of business (i.e. copiers, scanners, consumer digital, professional imaging, and health imaging). He has held positions in product & tooling design engineering, manufacturing engineering, project management, quality management, and globalization. Early in his career, as part of a new product development (NPD) process reengineering effort, he established himself as a corporate subject matter expert in Value Analysis/Value Engineering (VA/VE) and Design for Manufacture & Assembly (DFMA®) and later expanded that expertise to Lean Six Sigma being certified as a Black Belt and becoming a corporate Lean Six Sigma instructor and mentor. He has developed and delivered corporate training and certification programs around the world.

As Director of DFMA® Implementation Services, Chris works with BDI customers to establish internal competency, aid corporate culture change, and apply DFMA® on key projects.

DFMA® Implementation Workshop

These hands-on workshops help teams quickly and effectively begin to use and implement DFMA® Product Costing and Simplification. Starting with an introduction to the DFMA® methodology and techniques, and concluding with analyses of your own products, it's a perfect method to begin integration of DFMA® into your company's product development and cost reduction process.

DFMA® Core Training

Boothroyd Dewhurst has developed the DFMA® Core Training course to cover the basic requirements needed to successfully analyze product designs using the Boothroyd Dewhurst methodology. Using BDI’s Design for Manufacture and Assembly software, emphasis is placed on using the DFMA® design philosophy in the design and redesign process. Hands on time with the software tools is maximized in this course.

Design for Value Workshop

DFMA® is viewed by many as a VAVE technique. A key input to any VAVE effort is sound, credible Voice of the Customer. This workshop integrates these three techniques together into a more complete set of product development and productivity improvement practices and applies them on your project(s).

Additional Consulting Services

DFMA® Guided Analysis

Workshop

A focused multi-day event designed to help an organization

understand how DFMA® can apply to its business. Our

DFMA® expert will facilitate your team through a DFMA®

analysis of one of your products including redesign

brainstorming and quantification of redesign concepts.

Process Development & DFMA®

Deployment

Integration of DFMA® into your company’s “standard

work”. Our Lean Six Sigma consultants can evaluate your

company practices and work with your process excellence leaders

to integrate DFMA® into existing corporate processes.

Competitive Product Assessment

Utilize DFMA® to assess and compare competitive

product(s) in a structured, objective way. Generate key

competitive landscape data to aid product planning and

development.

Contact your DFMA® salesperson for details of our additional services.

“Promoted a change in design methodology.”

“Opened closed minds to new methods of design.”

“Made you think from the beginning before you design.”

“Real world experience from other companies, not just academia.”

“Practical use with (our) product was a valuable part of the program.

“Everything has real life applications-you can’t make an argument not to use these workshops."