Redesign of Forklift Hydraulic Cylinders

Matthew Miles

Mechanical Engineer

The Raymond Corporation

Customers demand reliable, high-quality products at the lowest possible cost. Accordingly, it’s incumbent upon manufacturers such as The Raymond Corporation (“Raymond”) to continually streamline manufacturing to meet these needs. After adopting Boothroyd Dewhurst DFMA® cost-reduction software, Raymond engineers incorporated the tool across its line of electric forklift trucks. DFMA was used to assist in the redesign of the hydraulic cylinders on the Model 7400 Reach-Fork® truck, where part count was reduced significantly while maintaining product and component quality, functionality, reliability—and lowering cost.

The Raymond Corporation is a North American leader in the design and manufacture of narrow-aisle electric forklifts—from orderpickers and Swing-Reach® trucks to stand-up counterbalanced and Reach-Fork® trucks—providing material-handling solutions that improve warehousing and distribution efficiency.

Founded in Greene, New York, Raymond has repeatedly advanced the industry through innovation and product reliability: from the first commercially successful hydraulic hand lift truck, to early narrow-aisle and Reach-Fork® trucks, to computer-controlled drive systems and AC-powered Reach-Fork® platforms. A variety of industry-leading lift trucks are produced at plants in Greene, New York; Muscatine, Iowa; and Brantford, Ontario, Canada. Raymond is part of Toyota Material Handling Group.

Raymond initially trialed DFMA with small cross-functional teams using the software for part-count analysis on two weldments (an overhead guard and an operator display mount). The goal was to compare multiple design iterations and manufacturing options while preserving functionality, quality, and reliability. Both projects yielded opportunities to reduce part count and offset material/transportation increases.

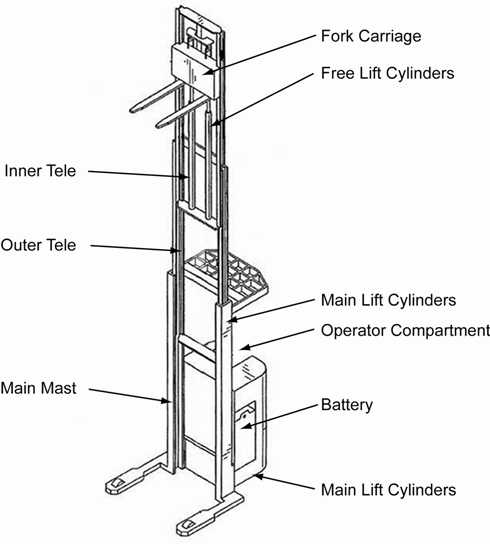

Building on this, the Mechanical Design Engineering (MDE) group applied DFMA more extensively during a large product improvement effort. To offset material and transportation increases on the Model 7400 Reach-Fork® truck, the team performed a detailed part-count analysis on the elevating section (three telescopic frames raised/lowered by hydraulic cylinders and lift chains). Many areas showed savings potential, but the hydraulic cylinders offered the most significant opportunity.

The elevating section uses two sets of hydraulic cylinders: “main lift” cylinders raise the outer telescopic mast (which then raises the inner mast via chains), while “free lift” cylinders elevate the fork carriage along the inner mast without extending the overall mast height—maintaining overall collapsed height (OACH) for door and clearance transitions. At full extension of the free-lift cylinders, the hydraulic system begins extending the main-lift cylinders: this transition is called “staging.”

Raymond developed a staging free-lift cylinder (U.S. Patent No. 6,557,456 B2) that cushions the fork carriage and load during staging, reducing noise and shock. The redesign effort focused on lowering part count and cost without degrading cushioning or increasing noise.

Engineers brainstormed design concepts and used DFMA to estimate cost changes quickly for each iteration. A DFMA baseline established current cost; redesigns were then compared against this baseline. Promising designs were prototyped, cycled to acceptable levels, and evaluated for performance. The selected redesign delivered equivalent cushioning and noise with fewer parts and lower cost.

Greene Manufacturing Operations contributed process improvements in parallel with the redesign. Both main and free-lift cylinder housings use drawn-over-mandrel steel tubing (electric resistance welded with flash removed). To enhance manufacturability and reduce cost, machining operations on the cylinder housing were eliminated where possible.

Analysis of the internal assemblies increased commonality between main and free-lift cylinders. The staging cylinders borrowed the lower cushion assembly from the main-lift cylinders (both act as cushions during mast retraction), increasing annual volumes and lowering part costs.

Assemblies were analyzed with DFA; new and selected existing parts were analyzed with DFM Concurrent Costing®. Results showed clear reductions in assembly part count and supported Purchasing in sourcing the redesigned parts. The free-lift staging cylinder comparison is shown below.

| Existing Free-Lift Cylinder | New Free-Lift Cylinder | |

|---|---|---|

| Number of parts | 37 | 28 |

| Estimated labor (sec) | 964 | 734 |

| DFA Index | 8.7 | 12.7 |

Using DFMA allowed Raymond engineers to identify high-impact part-count reductions early. Overall, manufacturing costs for the Model 7400 Reach-Fork® truck’s main and free-lift cylinders were reduced to offset material and transportation pressures. The free-lift staging cylinders realized the largest part-count drop—from 37 to 28 parts. Part-number inventories also decreased: the truck moved from multiple main-lift cylinder part numbers to a single common part, and free-lift cylinder part numbers were reduced as well. Associated hydraulic lines were updated and simplified, improving assembly efficiency.

Based on the success of these improvement projects and growing DFMA experience, Raymond has been formalizing recommended practices for using DFMA in development. The goal is to deploy DFMA at project inception as a cost-attainment tool—estimating part count and cost from start to finish. A database of Greene Operations machinery is being built within DFM to further align design with in-house capability.