Do you know what each manufactured part in your product development should cost, or do you simply know what you usually pay for it?

You could be leaving money on the table if you stick with standard price analysis software and always go with the lowest bidder’s first offer.

If you’re ready to start negotiating better contracts and avoid continuing to overpay, your key to part design cost optimization lies in using manufacturing cost analysis software to conduct in-depth should cost analyses.

According to Federal Acquisition Regulation (FAR) guidelines, the definition of a price analysis is “the process of examining and evaluating a proposed price without evaluating its separate cost elements and proposed profit.”

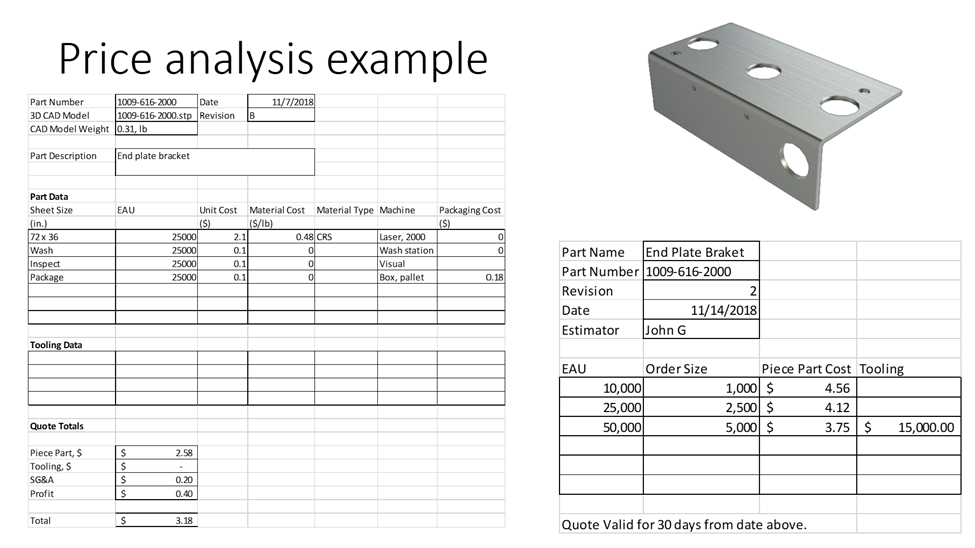

In other words, a price analysis is a broad-strokes estimate of the part’s ultimate manufacturing costs. Your analysis may look similar to this:

You may have noticed that there tends to be a lot of variation between quotes from different suppliers. Which supplier would you pick if you run three price analyses for a part and get the following results?

| Quote Number | Price, $ |

|---|---|

| Quote 1 | 3.18 |

| Quote 2 | 4.12 |

| Quote 3 | 2.44 |

Given no other information, you’d probably pick the third supplier ten out of ten times. After all, why choose a supplier that costs $3.18 or $4.12 when you found one that charges only $2.44 per part? The problem is that you have only one factor to consider.

Cost analysis is on the other side of the coin in a price quote. Cost analysis is defined by FAR as “the review and evaluation of any separate cost elements and profit or fee in an offeror’s or contractor’s proposal, as needed to determine a fair and reasonable price or to determine cost realism.”

Already, you can see how a should cost analysis might provide more context than a price quote as an assembly cost reduction method. A should cost analysis would reveal the individual components that go into an item’s total cost, the supplier’s fees, and the profit margin.

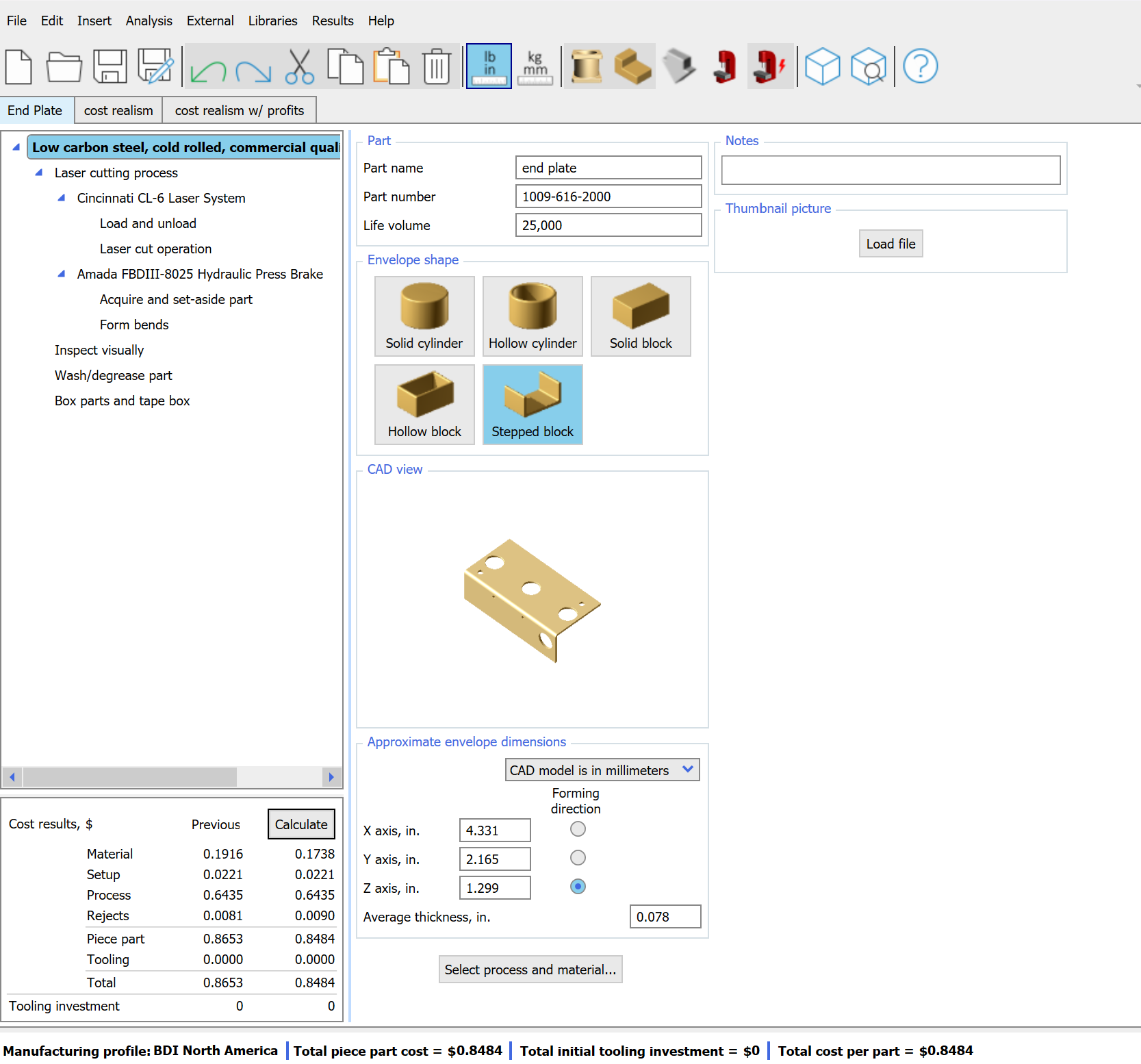

Using DFMA, you can accurately determine what each manufactured component should cost. Below is a sample of what a should cost analysis could be using DFMA:

DFMA software should cost analysis breakdown showing material, setup, process, rejects, and tooling costs.

Note the results in the bottom left window. You can see the material, setup, process, rejects, piece part, and tooling costs itemized in detail. You now have insight into what it should cost to manufacture the part in question, and you can compare that total to the quotes offered by your suppliers.

The prices in the Cost Realism column reflect the costs from the supplier’s quote. This includes the material cost, sheet size, and other factors. Add in a buffer for Supplier Selling, General, Administrative, and Profit (SGA&P) costs, and you’ll find the total item price based on your cost realism analysis:

| Results, $ | |

|---|---|

| Piece Part Cost | 1.4957 |

| Supplier SGA&P (18%) | 0.2692 |

| Price | 1.7649 |

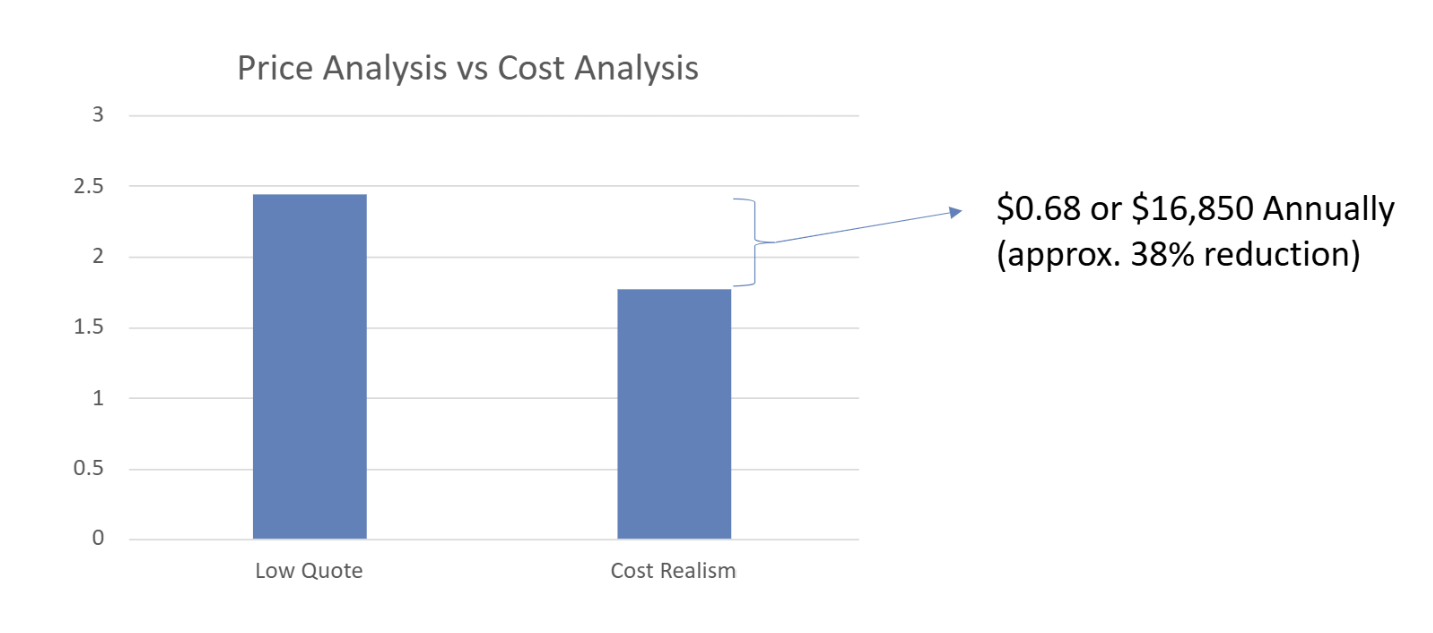

This is a 38% improvement over even the lowest quote generated from price analysis software (as opposed to detailed DFMA cost analysis software).

You can use this detailed information as leverage next time you negotiate a contract with your chosen supplier. Your exact savings may vary based on your negotiation, but the potential savings are incredible. Never accept the discrepancy between your DFMA cost analysis result and the supplier’s quote! If you can reconcile the difference between your results and the supplier’s quote using should costing, you’ll have the information to secure the best contract possible.

Additionally, remember that the $16,850 difference every year is for just one part. Extrapolate these results across numerous parts and various suppliers and you can see how using a DFMA should cost analysis could uncover savings you’d never be able to find if you used standard price quote software.

Do you want to start saving money today on parts production costs? Contact us to find out how!