As a manufacturer, your competitiveness depends on your ability to understand cost drivers early in the development lifecycle. The sooner you anticipate costs, the more you can revamp your processes to improve cost efficiency.

Here’s how DFMA part cost analysis can give you the insights you need to save money and streamline development.

Part cost analysis, often referred to as “should costing,” is a foundational element of the Design for Manufacture and Assembly (DFMA) methodology. It’s a process that determines the true, optimal cost of a component before you even begin production. In other words, it’s your way of knowing what the part should cost under ideal circumstances, so you can shave down your real-world costs to match. This is crucial because the majority of a product’s total cost is locked in during the initial design phases.

Our part should-cost analysis service, using DFMA software, where we do the analysis for you and provide you with actionable information you can use right away. It gives you:

The model you receive from a DFMA part cost analysis is a powerful “what if” tool you can use to explore different outcomes. We will have already filled in the basics from our massive global database of labor, materials, and process costs. You’ll be able to fine-tune the factors that affect your costs to see how your decisions change the ultimate should-cost figure. For instance, you could test:

Once you know the true costs for your chosen component, you can negotiate with your suppliers. This means that supplier quotes won’t blindside you. Instead, you can shop around for a better option that more closely fits your realistic should-cost figure.

With quantifiable data points at your fingertips, you can make informed trade-offs as you conceptualize the manufacturing and assembly processes. For example, changing to a different material may increase part costs by a few cents each, but it will save so much time and effort during assembly or service that you more than make up for the up-front investment with savings down the line.

We have two classes of parts. The part class will determine the part cost analysis amount for each part.

Please contact us for the Class A and Class B part cost analysis service fees per part.

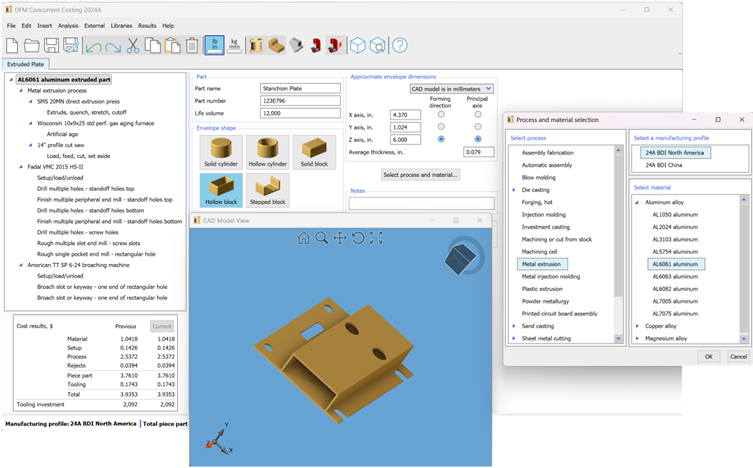

Each analysis includes all the data you need for an accurate should cost estimate. The example below shows the type of output you’ll receive once we’ve completed the technical analysis of the part’s geometry. You’ll find the results highlighted in color-coded sections labeled “basic data,” “part basic data,” “laser cut data,” and “press break data.” The figures presented here are reliable and provide a solid foundation for future modifications.

You can duplicate the model to run your own “what if” scenarios based on new supplier quotes or alternative design options under review. For instance, you might explore:

The updated calculations will appear in the cost results area located in the lower-left corner of the interface.

For the best results, it’s important to provide as much information as you can. The following are crucial:

The more information you can give us, the better we can build cost projections for you.

To take advantage of our analysis service, you will need:

Continuing the status quo without each part being optimized for cost efficiency is leaving money on the table. A simple redesign, based on our part cost analysis, may save you millions in future development costs.

If you're ready to have us do a part cost analysis to determine what your parts should optimally cost, contact us now.